Tap, tap, is this thing on? I have far too many project posts languishing in the queue. Here is one.

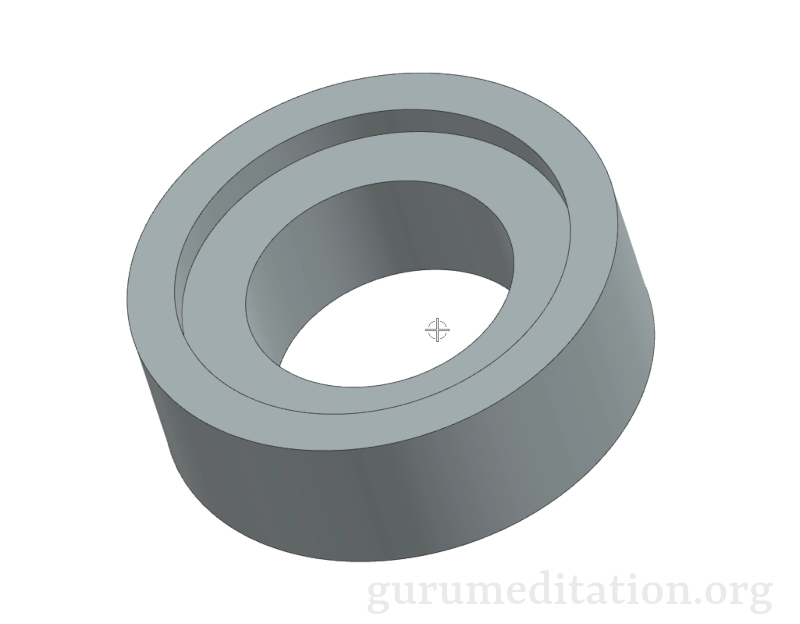

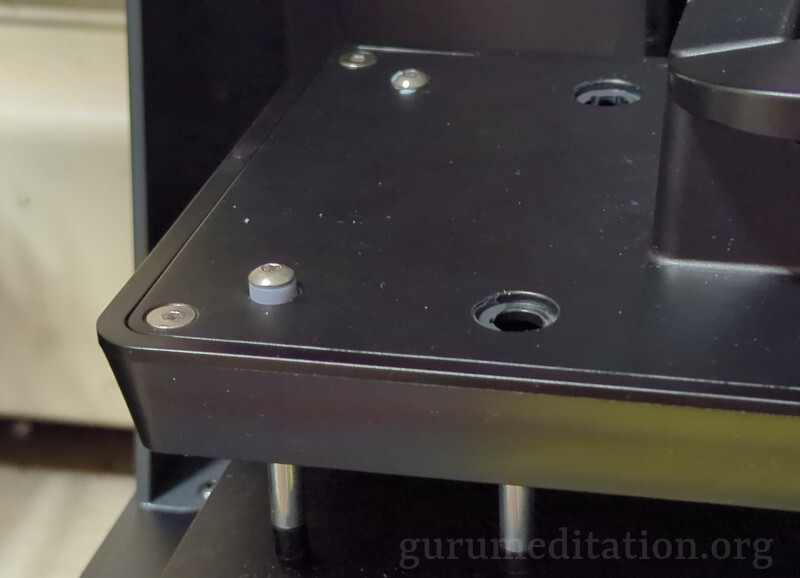

These are little washers that go on the screws of the Saturn 4 build plate in order to level it by pre-compressing the springs. The “automatic leveling” can’t adjust for lateral tilt and I’m not convinced it works 100% for longitudinal either. I was having problems when I printed at certain locations on the build plate there would be layer shifts, crushed layers, or the model would get broken off. Using one of these washers (0.45mm) I was able to manually level my plate.

I used a longer M4 10mm screw but the stock M4 5mm screws might(?) work also.

I printed these in resin but a metal version like stainless steel would be nice. It might be possible to print these with FDM but it will be a bit fiddley to get the dimensions exactly correct. In the future I may make a larger diameter version that could make use of a larger pan-head screw to spread out the pressure to prevent the washer from cracking but I’m not sure if this will be an issue.

This is a very simple object so I used OpenSCAD to make it easy for anyone to adjust the parameters. $lift being the main parameter to set how far the plate will be lifted up. STL files can be be generated from the command line as such (Linux):

openscad -o pad_45.stl -D '$lift=0.45' saturn4-pad.scadNote that the indent on the washer faces DOWN so in most of these pictures you’re seeing the bottom. The pin moves up in to this indent and that pulls the plate upwards. Leveling can be tested by the standard method of lowering the plate close to the screen and slipping a folded piece of paper under each corner to make sure they’re all at the same position.

One response to “Leveling the Elegoo Saturn 4 build plate”

you’re a hero, mate