Project 130X.

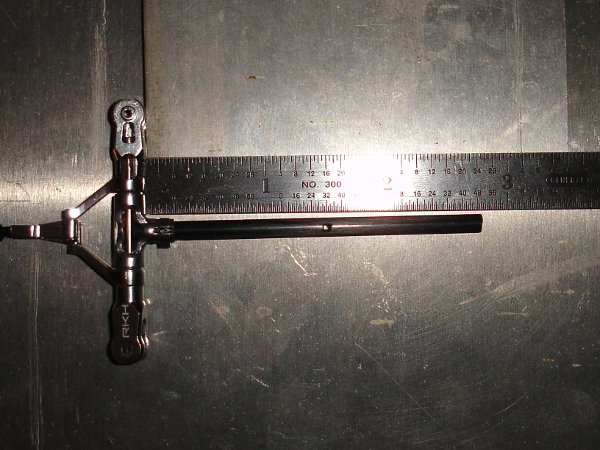

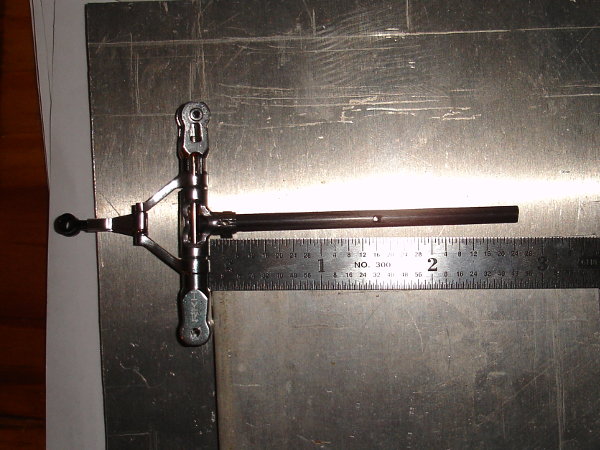

Had a Rakon DFC CNC head that was not square from the factory so I pounded on it with a hammer to make it straight.

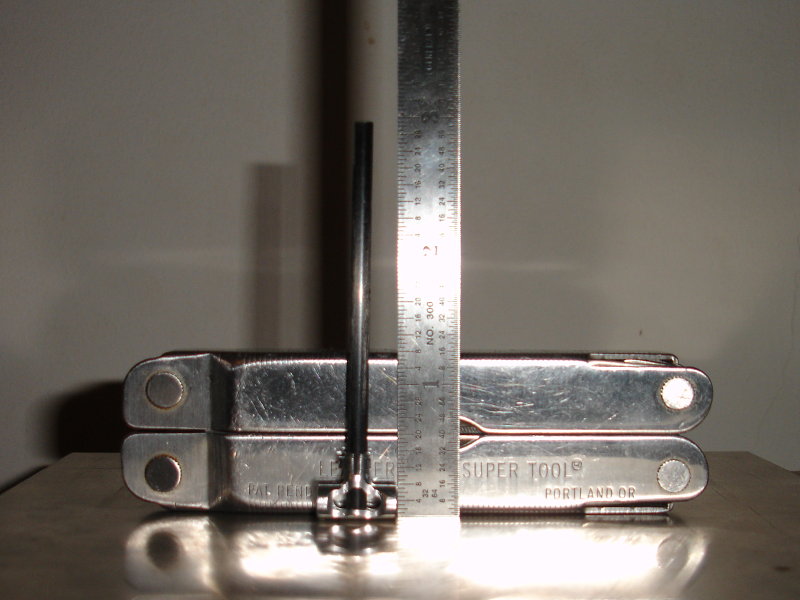

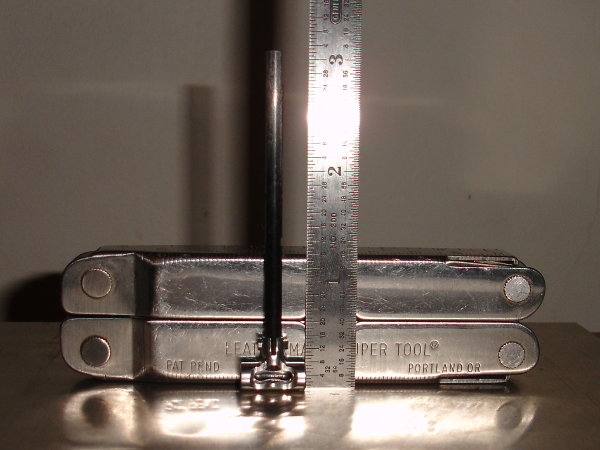

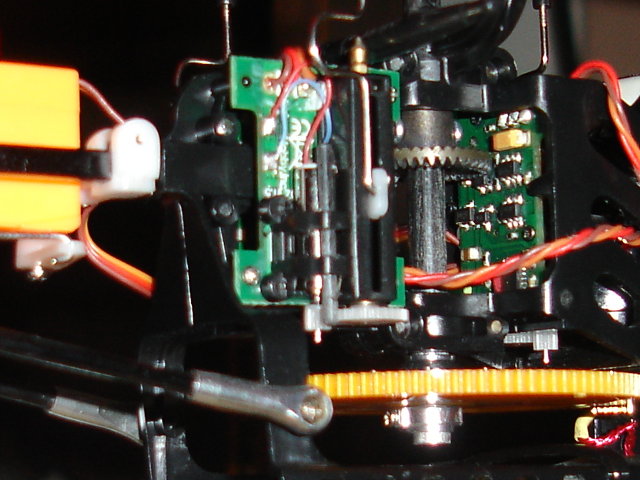

It appears to be possible to use an S107 tail motor to repair/replace the 130x servo motor. The S107 motor is 4mm and the servo motor is normally 5mm so there is some extra space. I used a piece of 1.5mm carbon rod to take up the extra space and it seems to work fine. I may try to find some other method of holding the motor in place. Also, rumour is that some S107 clones have 5mm tail motors.